Entebbe – Uganda Airlines has achieved a historic technical milestone after its Approved Maintenance Organisation (AMO) successfully performed its first engine change on one of the national carrier’s CRJ900 aircraft, registered as 5X-KNP. The achievement comes just days before the airline marks its sixth anniversary on August 28, 2025.

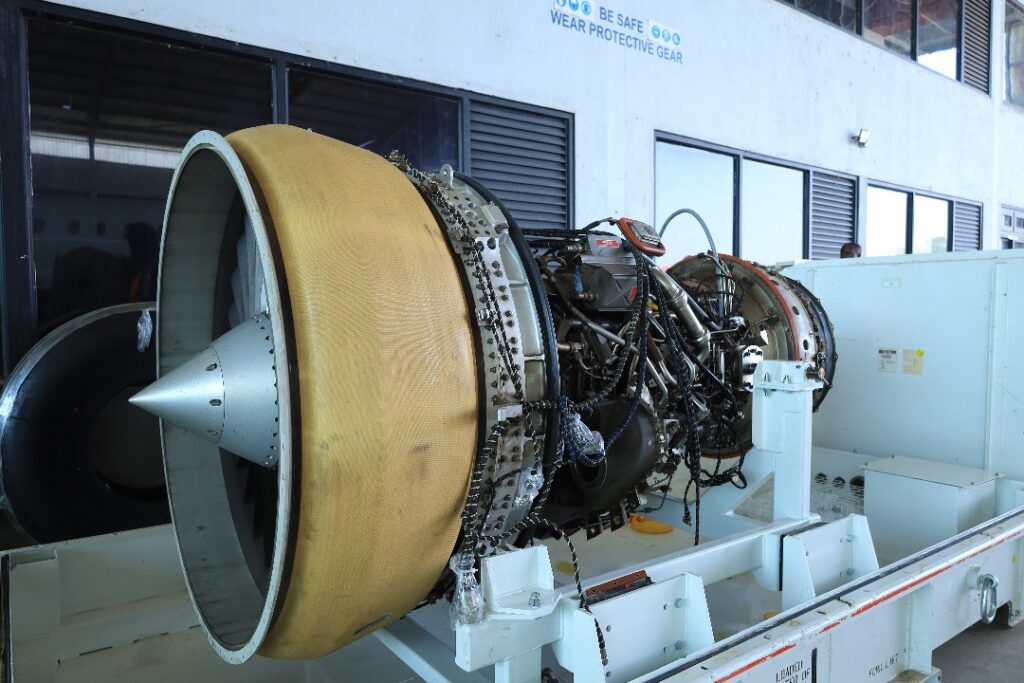

The complex operation, carried out on the aircraft’s left engine (Engine 1), involved removing the old unit and installing a brand-new General Electric CF34-8C5 engine. The removed engine will be shipped to the manufacturer for scheduled modifications and is expected to return later for installation on the right side, ensuring both engines undergo the required upgrades.

Though routine in global aviation, this engine change was groundbreaking for Uganda Airlines because it was the first to be performed entirely in-house by the airline’s AMO team since receiving certification from the Uganda Civil Aviation Authority in March 2024.

“This is a milestone achievement for our airline, our country, and the region,” said Peter Emuge, Head of Maintenance and Engineering at Uganda Airlines. “Until now, such operations had to be carried out abroad. With our AMO, we now have the capacity to handle top-level technical work locally, using Ugandan engineers.”

Emuge explained that while an engine change typically takes about 48 hours, the airline allowed more time for this first attempt to give young engineers full learning exposure. “The cost of outsourcing such a job abroad often exceeds USD 100,000, excluding ferrying the aircraft and handling expenses. Doing it here saves the airline and the country significant money,” he noted.

Building Ugandan Expertise

The Uganda Airlines AMO is staffed by highly experienced engineers recruited internationally, but the airline has invested heavily in building local expertise. Currently, 18 graduate trainees from Soroti Flying School and leading universities like Makerere are undergoing hands-on mentorship, with a goal of attaining aircraft maintenance licenses within three years.

“When Uganda Airlines restarted, some people doubted whether Ugandans could handle such technical work,” said Uganda Airlines CEO Jenifer Bamuturaki. “Today, our engineers have proven themselves. We are training the next generation of managers, pilots, and engineers so that this airline becomes fully Ugandan-led.”

Bamuturaki highlighted the growing role of women in aviation engineering. Graduate trainees are already involved in engine projects, while women also serve as development engineers, materials managers, and records officers. “This is significant because six years ago, many of our engineers were not yet fully trained. Young women now are taking up technical roles and excelling,” she said.

Operational and Financial Impact

According to Joseph Lukwago, Head of Line Maintenance at Uganda Airlines, the airline has cut costs drastically since taking over maintenance operations from Dutch company SAMCO in August 2023.

“Previously, Uganda Airlines spent between UGX 800 million and 1 billion per month on outsourced maintenance. By doing the work ourselves, we have significantly reduced these costs,” Lukwago explained. “Flying this aircraft abroad for the engine change would have cost us about USD 10,000 in fuel plus over USD 100,000 for the procedure. Doing it in Uganda saves millions.”

Lukwago added that about 45 staff are involved in line maintenance, including engineers, assistants, and trainees. About six women are actively involved in this engine change project—a great milestone for gender inclusion in aviation engineering.

“For us, that is a milestone in gender inclusion in aviation maintenance. We are proud of the growing number of women in our engineering team, including: a technical records officer (female), a materials manager in charge of spares (female) and a development engineer overseeing all engines in the company (female).”

Growth and Strategic Outlook

The engine change underscores broader progress for Uganda Airlines as it positions itself for long-term sustainability. Passenger numbers have grown from 70,000 in 2019 to more than 419,000 in the last financial year, bringing the cumulative total since relaunch to over 1.2 million.

“We started with just five flights daily in 2019,” said Bamuturaki. “Today, we operate nearly 59 flights a day, more than 580 weekly. Our cargo operations are expanding, and our London route has been a breakthrough in terms of revenue, recognition, and tourism promotion.”

While appearing before the Committee on Commissions, Statutory Authorities and State Enterprises (COSASE) to respond to queries raised in the 2024 Auditor General’s report, Bamuturaki said that when Uganda Airlines commenced operations in 2019, its annual revenue stood at Shs 28.5 billion. Over time, the figure has grown consistently, demonstrating resilience and an ability to withstand economic shocks such as the COVID-19 pandemic that grounded global aviation.

Bamuturaki told journalists at the Entebbe-based EagleAir Hangar on Friday that Uganda Airlines is working towards becoming a net contributor to government revenues. “With support, training, and partnerships, we can grow into a sustainable, globally respected national carrier,” she added.

Spare Parts & Global Supply Chain Challenges

Despite the progress, the airline acknowledges challenges. Spare parts delays remain a global issue due to supply chain disruptions after COVID-19, but Emuge reassured that Uganda Airlines has mitigation strategies such as predictive maintenance and supplier partnerships.

Both Bamuturaki and Emuge addressed the recent public concern about aircraft spare parts to set the record straight and put rumours to rest.

“The challenge is global, not unique to Uganda Airlines. After COVID-19, many aircraft manufacturers slowed production. With the strong rebound in travel, there has been pressure on supply chains and raw materials,” explained Emuge.

He added, “As a result, parts take longer to arrive and prices have gone up. However, spare parts are available, especially for our CRJ aircraft engines (GE-powered). The delays are due to supply-demand imbalances, not lack of parts.”

Bamuturaki, on her part, said the matter had been blown out of proportion. “The current engine replacement process takes about three months. Fortunately, because we had pre-ordered spare engines with government support, we can continue operating while the engines rotate for maintenance,” she noted.

She added, “It is disappointing when Ugandans undermine their own national airline. Unlike in other countries, where citizens proudly support their carriers, we often face unnecessary negativity. I urge Ugandans to support their airline, because its success benefits the whole economy.”

For Uganda Airlines, the first in-house engine change is more than a technical milestone—it is a statement of national progress. “Uganda Airlines is still young, but the progress we’ve made shows what is possible,” Bamuturaki said. “We are building something that will serve generations to come.”